Replacement Engines

The idea of sourcing a replacement engine for your car can certainly be a daunting one. Most of us lack the sufficient knowledge or the expertise in doing so and are often put off by the fear of being ripped off. Here at MKL Motors we have a friendly team with knowledge in the field who are happy to offer you advice to make the process of sourcing a replacement as easy as possible. With a sophisticated database in-place we can quickly identify exactly which replacement engine is required for your vehicle. We also have a number of links to various fitters so we can certainly make it a pain free process and have your car back on the round in no time.

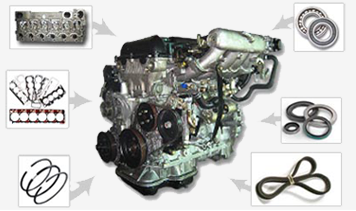

All Reconditioned Replacement Engines have had the following work done:

- Brand new head gasket is fitted

- Brand new big end bearings are fitted

- Brand new main bearings are fitted

- The cylinder head is thoroughly pressure tested

- The cylinder head is skimmed and valves are re-seated

- Brand new valve seals fitted

- The camshaft is thoroughly inspected

- The crankshaft is reground

- Brand new crankshaft bearings are installed

- The oil pump is thoroughly inspected

- The oil Pressure is tested

- Oil leaks tests are conducted

- Brand new piston rings are fitted

- Brand new piston liners are installed

Production Process for Reconditioned Replacement Engines :

TESTING

Where possible units are taken from vehicles and tested for overall condition where the engine is run through a diagnostic program and compression tested.

DISMANTLING

The units are then dismantled by experienced engineers where all working parts are checked and worn parts are discarded.

PARTS REPLACEMENT

After dismantling all worn and discarded parts are replaced with brand new parts. Our supplier uses high quality parts to ensure you receive an excellent product built to last.

ASSEMBLY

Once the parts are replaced our experienced engineers assemble the units to exact manufacturer specific standards

WASHING

All units are thoroughly washed, once dry the units are then painted or sand blasted so that the external condition reflects the excellent internal condition of the engine.

FINAL TESTING

In the final testing phase many units are started and run on a bench test before being put through a compression test and engine diagnostic to ensure you receive the most reliable unit.