9am - 6pm

- Remanufactured Alfa Romeo Engines

- Remanufactured Alfa Romeo Engines

- Remanufactured Alfa Romeo 4C Engines

- Remanufactured Alfa Romeo MiTo Engines

- Remanufactured Alfa Romeo 33 Engines

- Remanufactured Alfa Romeo GTV Engines

- Remanufactured Alfa Romeo 164 Engines

- Remanufactured Alfa Romeo GT Engines

- Remanufactured Alfa Romeo 166 Engines

- Remanufactured Alfa Romeo Brera Engines

- Remanufactured Alfa Romeo 155 Engines

- Remanufactured Alfa Romeo 156 Engines

- Remanufactured Alfa Romeo 159 Engines

- Remanufactured Alfa Romeo 145 Engines

- Remanufactured Alfa Romeo 146 Engines

- Remanufactured Alfa Romeo 147 Engines

- Remanufactured Alfa Romeo Spider Engines

- Remanufactured Alfa Romeo 75 Engines

- Remanufactured Audi Engines

- Remanufactured Audi Engines

- Remanufactured Audi TT Engines

- Remanufactured Audi Q7 Engines

- Remanufactured Audi Q5 Engines

- Remanufactured Audi Q3 Engines

- Remanufactured Audi A8 Engines

- Remanufactured Audi A7 Engines

- Remanufactured Audi A6 Engines

- Remanufactured Audi A5 Engines

- Remanufactured Audi A4 Engines

- Remanufactured Audi A3 Engines

- Remanufactured Audi A2 Engines

- Remanufactured Audi A1 Engines

- Remanufactured BMW Engines

- Remanufactured BMW 323 Engines

- Remanufactured BMW 640 Engines

- Remanufactured BMW 540 Engines

- Remanufactured BMW X6 Engines

- Remanufactured BMW F20 Engines

- Remanufactured BMW E61 Engines

- Remanufactured BMW 725 Engines

- Remanufactured BMW E82 Engines

- Remanufactured BMW 325 Engines

- Remanufactured BMW E39 Engines

- Remanufactured BMW F11 Engines

- Remanufactured BMW Z8 Engines

- Remanufactured BMW 528 Engines

- Remanufactured BMW E87 Engines

- Remanufactured BMW 635 Engines

- Remanufactured BMW 750 Engines

- Remanufactured BMW 330 Engines

- Remanufactured BMW F07 Engines

- Remanufactured BMW F10 Engines

- Remanufactured BMW F12 Engines

- Remanufactured BMW 530 Engines

- Remanufactured BMW M5 Engines

- Remanufactured BMW 525 Engines

- Remanufactured BMW E67 Engines

- Remanufactured BMW I8 Engines

- Remanufactured BMW 135 Engines

- Remanufactured BMW 130 Engines

- Remanufactured BMW 128 Engines

- Remanufactured BMW 125 Engines

- Remanufactured BMW 123 Engines

- Remanufactured BMW 120 Engines

- Remanufactured BMW 118 Engines

- Remanufactured BMW 1 Series Engines

- Remanufactured BMW E60 Engines

- Remanufactured BMW 760 Engines

- Remanufactured BMW 228i Engines

- Remanufactured BMW 220d Engines

- Remanufactured BMW 220i Engines

- Remanufactured BMW 2 Series Engines

- Remanufactured BMW 114 Engines

- Remanufactured BMW Engines

- Remanufactured BMW 650 Engines

- Remanufactured BMW 316 Engines

- Remanufactured BMW E46 Engines

- Remanufactured BMW 3 Series Engines

- Remanufactured BMW X4 Engines

- Remanufactured BMW 328 Engines

- Remanufactured BMW F01 Engines

- Remanufactured BMW 116 Engines

- Remanufactured BMW E63 Engines

- Remanufactured BMW 320 Engines

- Remanufactured BMW E93 Engines

- Remanufactured BMW F02 Engines

- Remanufactured BMW 335 Engines

- Remanufactured BMW 730 Engines

- Remanufactured BMW F30 Engines

- Remanufactured BMW E92 Engines

- Remanufactured BMW E81 Engines

- Remanufactured BMW E38 Engines

- Remanufactured BMW 740 Engines

- Remanufactured BMW I3 Engines

- Remanufactured BMW 520 Engines

- Remanufactured BMW 523 Engines

- Remanufactured BMW 5 Series Engines

- Remanufactured BMW Z3 Engines

- Remanufactured BMW E88 Engines

- Remanufactured BMW M3 Engines

- Remanufactured BMW E90 Engines

- Remanufactured BMW Z4 Engines

- Remanufactured BMW F33 Engines

- Remanufactured BMW 728 Engines

- Remanufactured BMW X1 Engines

- Remanufactured BMW X5 Engines

- Remanufactured BMW E64 Engines

- Remanufactured BMW 645 Engines

- Remanufactured BMW E68 Engines

- Remanufactured BMW 7 Series Engines

- Remanufactured BMW 535 Engines

- Remanufactured BMW 735 Engines

- Remanufactured BMW E65 Engines

- Remanufactured BMW M6 Engines

- Remanufactured BMW 630 Engines

- Remanufactured BMW E36 Engines

- Remanufactured BMW X3 Engines

- Remanufactured BMW F36 Engines

- Remanufactured BMW 6 Series Engines

- Remanufactured BMW F21 Engines

- Remanufactured BMW E91 Engines

- Remanufactured BMW F32 Engines

- Remanufactured BMW E66 Engines

- Remanufactured BMW 745 Engines

- Remanufactured BMW 4 Series Engines

- Remanufactured BMW F13 Engines

- Remanufactured BMW 318 Engines

- Remanufactured Citroen Engines

- Remanufactured Citroen C8 Engines

- Remanufactured Citroen Dispatch Engines

- Remanufactured Citroen DS4 Engines

- Remanufactured Citroen Engines

- Remanufactured Citroen C5 Engines

- Remanufactured Citroen C6 Engines

- Remanufactured Citroen DS3 Engines

- Remanufactured Citroen C3 Plurial Engines

- Remanufactured Citroen C4 Engines

- Remanufactured Citroen C4 Picasso Engines

- Remanufactured Citroen C2 Engines

- Remanufactured Citroen C3 Engines

- Remanufactured Citroen C3 Picasso Engines

- Remanufactured Citroen C-Zero Engines

- Remanufactured Citroen Berlingo Engines

- Remanufactured Citroen C-Crosser Engines

- Remanufactured Citroen C4 Aircross Engines

- Remanufactured Citroen Evasion Engines

- Remanufactured Citroen Xantia Engines

- Remanufactured Citroen Xsara Engines

- Remanufactured Citroen Synergie Engines

- Remanufactured Citroen DS5 Engines

- Remanufactured Citroen Nemo Engines

- Remanufactured Citroen C1 Engines

- Remanufactured Citroen Saxo Engines

- Remanufactured Daewoo Engines

- Remanufactured Daihatsu Engines

- Remanufactured Fiat Engines

- Remanufactured Fiat Stilo Engines

- Remanufactured Fiat Strada Engines

- Remanufactured Fiat Engines

- Remanufactured Fiat Punto Engines

- Remanufactured Fiat Scudo Engines

- Remanufactured Fiat Sedici Engines

- Remanufactured Fiat Seicento Engines

- Remanufactured Fiat Linea Engines

- Remanufactured Fiat Marea Engines

- Remanufactured Fiat Multipla Engines

- Remanufactured Fiat Palio Engines

- Remanufactured Fiat Doblo Engines

- Remanufactured Fiat Fiorino Engines

- Remanufactured Fiat Grande Punto Engines

- Remanufactured Fiat Idea Engines

- Remanufactured Fiat 500 Engines

- Remanufactured Fiat Barchetta Engines

- Remanufactured Fiat Brava Engines

- Remanufactured Fiat Bravo Engines

- Remanufactured Ford Engines

- Remanufactured Ford S-Max Engines

- Remanufactured Ford Galaxy Engines

- Remanufactured Ford Cougar Engines

- Remanufactured Ford Transit Engines

- Remanufactured Ford Transit Engines

- Remanufactured Ford Ranger Engines

- Remanufactured Ford Mondeo Engines

- Remanufactured Ford Focus Engines

- Remanufactured Ford Fiesta Engines

- Remanufactured Ford Expedition Engines

- Remanufactured Ford EcoSport Engines

- Remanufactured Ford C-Max Engines

- Remanufactured Ford Windstar Engines

- Remanufactured Ford Mustang Engines

- Remanufactured Ford Kuga Engines

- Remanufactured Ford Ka Engines

- Remanufactured Ford Fusion Engines

- Remanufactured Ford B-Max Engines

- Remanufactured Ford Explorer Engines

- Remanufactured Ford Flex Engines

- Remanufactured Honda Engines

- Remanufactured Honda S2000 Engines

- Remanufactured Honda Stream Engines

- Remanufactured Honda Engines

- Remanufactured Honda FRV Engines

- Remanufactured Honda HRV Engines

- Remanufactured Honda Insight Engines

- Remanufactured Honda Integra Engines

- Remanufactured Honda Accord Engines

- Remanufactured Honda Civic Engines

- Remanufactured Honda CRV Engines

- Remanufactured Honda CRZ Engines

- Remanufactured Hyundai Engines

- Remanufactured Hyundai Santa Fe Engines

- Remanufactured Hyundai Sonata Engines

- Remanufactured Hyundai Terracan Engines

- Remanufactured Hyundai Engines

- Remanufactured Hyundai iLoad Engines

- Remanufactured Hyundai ix20 Engines

- Remanufactured Hyundai ix35 Engines

- Remanufactured Hyundai ix55 Engines

- Remanufactured Hyundai Matrix Engines

- Remanufactured Hyundai I20 Engines

- Remanufactured Hyundai I30 Engines

- Remanufactured Hyundai I40 Engines

- Remanufactured Hyundai I800 Engines

- Remanufactured Hyundai Coupe Engines

- Remanufactured Hyundai Elantra Engines

- Remanufactured Hyundai Equus Engines

- Remanufactured Hyundai Getz Engines

- Remanufactured Hyundai Grandeur Engines

- Remanufactured Hyundai I10 Engines

- Remanufactured Hyundai Veloster Engines

- Remanufactured Hyundai XG30 Engines

- Remanufactured Hyundai Trajet Engines

- Remanufactured Hyundai Tucson Engines

- Remanufactured Hyundai Accent Engines

- Remanufactured Isuzu Engines

- Remanufactured Jaguar Engines

- Remanufactured Jaguar XJ8 Engines

- Remanufactured Jaguar XK Engines

- Remanufactured Jaguar XK8 Engines

- Remanufactured Jaguar Engines

- Remanufactured Jaguar XF Engines

- Remanufactured Jaguar XJ Engines

- Remanufactured Jaguar XJ12 Engines

- Remanufactured Jaguar XJ6 Engines

- Remanufactured Jaguar F-Type Engines

- Remanufactured Jaguar S-Type Engines

- Remanufactured Jaguar X-Type Engines

- Remanufactured Jaguar XE Engines

- Remanufactured Jeep Engines

- Remanufactured Kia Engines

- Remanufactured Kia Sorento Engines

- Remanufactured Kia Soul Engines

- Remanufactured Kia Sportage Engines

- Remanufactured Kia Venga Engines

- Remanufactured Kia Engines

- Remanufactured Kia Magentis Engines

- Remanufactured Kia Opirus Engines

- Remanufactured Kia Picanto Engines

- Remanufactured Kia Rio Engines

- Remanufactured Kia Sedona Engines

- Remanufactured Kia Carens Engines

- Remanufactured Kia Carnival Engines

- Remanufactured Kia Cee’d Engines

- Remanufactured Kia Cerato Engines

- Remanufactured Kia Forte Engines

- Remanufactured Land Rover Engines

- Remanufactured Lexus Engines

- Remanufactured Lexus IS200 Engines

- Remanufactured Lexus Engines

- Remanufactured Lexus IS Engines

- Remanufactured Lexus LS400 Engines

- Remanufactured Lexus LS Engines

- Remanufactured Lexus IS350 Engines

- Remanufactured Lexus IS300 Engines

- Remanufactured Lexus IS250 Engines

- Remanufactured Lexus IS220 Engines

- Remanufactured Lexus GS450 Engines

- Remanufactured Lexus GS300 Engines

- Remanufactured Lexus GS Engines

- Remanufactured Lexus ES350 Engines

- Remanufactured Lexus ES330 Engines

- Remanufactured Lexus ES300 Engines

- Remanufactured Lexus ES Engines

- Remanufactured Lexus CT400 Engines

- Remanufactured Lexus CT300 Engines

- Remanufactured Lexus CT200 Engines

- Remanufactured Lexus CT Engines

- Remanufactured Lexus LS430 Engines

- Remanufactured Lexus RX330 Engines

- Remanufactured Lexus LS600 Engines

- Remanufactured Lexus RX300 Engines

- Remanufactured Lexus RX350 Engines

- Remanufactured Lexus RX450 Engines

- Remanufactured Lexus RX400 Engines

- Remanufactured Maserati Engines

- Remanufactured Mazda Engines

- Remanufactured Mazda MX5 Engines

- Remanufactured Mazda Premacy Engines

- Remanufactured Mazda RX8 Engines

- Remanufactured Mazda Tribute Engines

- Remanufactured Mazda Xedos Engines

- Remanufactured Mazda Engines

- Remanufactured Mazda CX7 Engines

- Remanufactured Mazda Demio Engines

- Remanufactured Mazda CX5 Engines

- Remanufactured Mazda MPV Engines

- Remanufactured Mazda B2500 Engines

- Remanufactured Mazda BT50 Engines

- Remanufactured Mazda 2 Engines

- Remanufactured Mazda 5 Engines

- Remanufactured Mazda 6 Engines

- Remanufactured Mercedes Engines

- Remanufactured Mercedes C32 Engines

- Remanufactured Mercedes Vito Engines

- Remanufactured Mercedes Engines

- Remanufactured Mercedes B250 Engines

- Remanufactured Mercedes B220 Engines

- Remanufactured Mercedes B55 Engines

- Remanufactured Mercedes B200 Engines

- Remanufactured Mercedes B180 Engines

- Remanufactured Mercedes B160 Engines

- Remanufactured Mercedes B170 Engines

- Remanufactured Mercedes B-Class Engines

- Remanufactured Mercedes A45 Engines

- Remanufactured Mercedes A280 Engines

- Remanufactured Mercedes A220 Engines

- Remanufactured Mercedes A180 Engines

- Remanufactured Mercedes A200 Engines

- Remanufactured Mercedes A150 Engines

- Remanufactured Mercedes A210 Engines

- Remanufactured Mercedes A170 Engines

- Remanufactured Mercedes A190 Engines

- Remanufactured Mercedes A160 Engines

- Remanufactured Mercedes A140 Engines

- Remanufactured Mercedes A-Class Engines

- Remanufactured Mercedes W205 Engines

- Remanufactured Mercedes W215 Engines

- Remanufactured Mercedes C280 Engines

- Remanufactured Mercedes W204 Engines

- Remanufactured Mercedes SL500 Engines

- Remanufactured Mercedes Sprinter Engines

- Remanufactured Mercedes C220 Engines

- Remanufactured Mercedes C30 Engines

- Remanufactured Mercedes C180 Engines

- Remanufactured Mercedes W202 Engines

- Remanufactured Mercedes C230 Engines

- Remanufactured Mercedes C55 Engines

- Remanufactured Mercedes W203 Engines

- Remanufactured Mercedes C250 Engines

- Remanufactured Mercedes V-Class Engines

- Remanufactured Mercedes C240 Engines

- Remanufactured Mercedes SL-Class Engines

- Remanufactured Mercedes E-Class Engines

- Remanufactured Mercedes GL-Class Engines

- Remanufactured Mercedes SLK200 Engines

- Remanufactured Mercedes C-Class Engines

- Remanufactured Mercedes W168 Engines

- Remanufactured Mercedes Citan Engines

- Remanufactured Mercedes E240 Engines

- Remanufactured Mercedes CLS-Class engines

- Remanufactured Mercedes R-Class Engines

- Remanufactured Mercedes C43 Engines

- Remanufactured Mercedes CL-Class Engines

- Remanufactured Mercedes SLS Engines

- Remanufactured Mercedes C36 Engines

- Remanufactured Mercedes C300 Engines

- Remanufactured Mercedes C350 Engines

- Remanufactured Mercedes GLA-Class Engines

- Remanufactured Mercedes W245 Engines

- Remanufactured Mercedes Vario Engines

- Remanufactured Mercedes M-Class Engines

- Remanufactured Mercedes GLK-Class Engines

- Remanufactured Mercedes S250 Engines

- Remanufactured Mercedes C63 Engines

- Remanufactured Mercedes W169 Engines

- Remanufactured Mercedes CLS500 Engines

- Remanufactured Mercedes W176 Engines

- Remanufactured Mercedes C200 Engines

- Remanufactured Mercedes CLA-Class Engines

- Remanufactured Mercedes G-Class Engines

- Remanufactured Mercedes S-Class Engines

- Remanufactured Mercedes SLK-Class Engines

- Remanufactured Mercedes Viano Engines

- Remanufactured MG Engines

- Remanufactured Mini Engines

- Remanufactured Mini Paceman Engines

- Remanufactured Mini Roadster Engines

- Remanufactured Mini Engines

- Remanufactured Mini Clubman Engines

- Remanufactured Mini Countryman Engines

- Remanufactured Mini Coupe Engines

- Remanufactured Mini Hatch Engines

- Remanufactured Mini Hardtop Engines

- Remanufactured Mini One Engines

- Remanufactured Mitsubishi Engines

- Remanufactured Mitsubishi Lancer Engines

- Remanufactured Mitsubishi Mirage Engines

- Remanufactured Mitsubishi Engines

- Remanufactured Mitsubishi L400 Engines

- Remanufactured Mitsubishi Space Runner Engines

- Remanufactured Mitsubishi L200 Engines

- Remanufactured Mitsubishi L300 Engines

- Remanufactured Mitsubishi Delica Engines

- Remanufactured Mitsubishi Shogun Engines

- Remanufactured Mitsubishi Eclipse Engines

- Remanufactured Mitsubishi Galant Engines

- Remanufactured Mitsubishi Grandis Engines

- Remanufactured Mitsubishi I-Miev Engines

- Remanufactured Mitsubishi Outlander Engines

- Remanufactured Mitsubishi RVR Engines

- Remanufactured Mitsubishi Carisma Engines

- Remanufactured Mitsubishi Challenger Engines

- Remanufactured Mitsubishi Colt Engines

- Remanufactured Nissan Engines

- Remanufactured Nissan Patrol Engines

- Remanufactured Nissan Pixo Engines

- Remanufactured Nissan Primastar Engines

- Remanufactured Nissan X-Trail Engines

- Remanufactured Nissan Engines

- Remanufactured Nissan Navara Engines

- Remanufactured Nissan Note Engines

- Remanufactured Nissan NV200 Engines

- Remanufactured Nissan NV400 Engines

- Remanufactured Nissan Pathfinder Engines

- Remanufactured Nissan Juke Engines

- Remanufactured Nissan Leaf Engines

- Remanufactured Nissan Maxima Engines

- Remanufactured Nissan Micra Engines

- Remanufactured Nissan Murano Engines

- Remanufactured Nissan Almera Engines

- Remanufactured Nissan Cube Engines

- Remanufactured Nissan Elgrand Engines

- Remanufactured Nissan Frontier Engines

- Remanufactured Nissan GTR Engines

- Remanufactured Nissan QashQai Engines

- Remanufactured Nissan Terrano Engines

- Remanufactured Nissan Tiida Engines

- Remanufactured Nissan Primera Engines

- Remanufactured Nissan Serena Engines

- Remanufactured Perkins Engines

- Remanufactured Peugeot Engines

- Remanufactured Peugeot 807 Engines

- Remanufactured Peugeot 207 Engines

- Remanufactured Peugeot Boxer Engines

- Remanufactured Peugeot 407 Engines

- Remanufactured Peugeot 307 Engines

- Remanufactured Peugeot 4008 Engines

- Remanufactured Peugeot 607 Engines

- Remanufactured Peugeot Partner Engines

- Remanufactured Peugeot 406 Engines

- Remanufactured Peugeot 107 Engines

- Remanufactured Peugeot 3008 Engines

- Remanufactured Peugeot iOn Engines

- Remanufactured Peugeot Engines

- Remanufactured Peugeot 4007 Engines

- Remanufactured Peugeot 206 Engines

- Remanufactured Peugeot RCZ Engines

- Remanufactured Peugeot J5 Engines

- Remanufactured Peugeot 208 Engines

- Remanufactured Peugeot Expert Engines

- Remanufactured Peugeot 5008 Engines

- Remanufactured Peugeot 308 Engines

- Remanufactured Peugeot Bipper Engines

- Remanufactured Peugeot 1007 Engines

- Remanufactured Peugeot 208 Engines

- Remanufactured Peugeot 106 Engines

- Remanufactured Peugeot E7 Engines

- Remanufactured Peugeot 508 Engines

- Remanufactured Porsche Engines

- Remanufactured Porsche Cayman Engines

- Remanufactured Porsche Cayenne Engines

- Remanufactured Porsche Engines

- Remanufactured Porsche Panamera Engines

- Remanufactured Porsche Macan Engines

- Remanufactured Porsche Cajun Engines

- Remanufactured Porsche Boxter Engines

- Remanufactured Porsche 911 Engines

- Remanufactured Porsche 918 Engines

- Remanufactured Porsche 991 Engines

- Remanufactured Porsche 996 Engines

- Remanufactured Porsche 997 Engines

- Remanufactured Range Rover Engines

- Remanufactured Renault Engines

- Remanufactured Renault Megane Engines

- Remanufactured Renault Engines

- Remanufactured Renault Laguna Engines

- Remanufactured Renault Latitude Engines

- Remanufactured Renault Master Engines

- Remanufactured Renault Mascott Engines

- Remanufactured Renault Fluence Engines

- Remanufactured Renault Modus Engines

- Remanufactured Renault Scenic Engines

- Remanufactured Renault Kangoo Engines

- Remanufactured Renault Koleos Engines

- Remanufactured Renault Twingo Engines

- Remanufactured Renault Avantime Engines

- Remanufactured Renault Captur Engines

- Remanufactured Renault Clio Engines

- Remanufactured Renault Espace Engines

- Remanufactured Renault Trafic Engines

- Remanufactured Renault Vel Satis Engines

- Remanufactured Renault Wind Engines

- Remanufactured Renault Zoe Engines

- Remanufactured Renault Twizy Engines

- Remanufactured Rover Engines

- Remanufactured Seat Engines

- Remanufactured Seat Engines

- Remanufactured Seat Toledo Engines

- Remanufactured Seat Leon Engines

- Remanufactured Seat Ibiza Engines

- Remanufactured Seat Exeo Engines

- Remanufactured Seat Cordoba Engines

- Remanufactured Seat Arosa Engines

- Remanufactured Seat Altea Engines

- Remanufactured Seat Alhambra Engines

- Remanufactured Skoda Engines

- Remanufactured Smart Engines

- Remanufactured SsangYong Korando Engines

- Remanufactured Subaru Engines

- Remanufactured Suzuki Engines

- Remanufactured Suzuki Engines

- Remanufactured Suzuki Wagon R Engines

- Remanufactured Suzuki SX4 Engines

- Remanufactured Suzuki Splash Engines

- Remanufactured Suzuki Liana Engines

- Remanufactured Suzuki Aerio Engines

- Remanufactured Suzuki Kizashi Engines

- Remanufactured Suzuki Ignis Engines

- Remanufactured Suzuki Grand Vitara Engines

- Remanufactured Suzuki Escudo Engines

- Remanufactured Suzuki Alto Engines

- Remanufactured Toyota Engines

- Remanufactured Toyota Landcruiser Engines

- Remanufactured Toyota Dyna Engines

- Remanufactured Toyota Engines

- Remanufactured Toyota Avensis Engines

- Remanufactured Toyota Tundra Engines

- Remanufactured Toyota Rav4 Engines

- Remanufactured Toyota Prius Engines

- Remanufactured Toyota Previa Engines

- Remanufactured Toyota Liteace Engines

- Remanufactured Toyota iQ Engines

- Remanufactured Toyota Hilux Engines

- Remanufactured Toyota HiAce Engines

- Remanufactured Toyota GT86 Engines

- Remanufactured Toyota 4Runner Engines

- Remanufactured Toyota Corolla Engines

- Remanufactured Toyota Celica Engines

- Remanufactured Toyota Camry Engines

- Remanufactured Toyota Aygo Engines

- Remanufactured Toyota Auris Engines

- Remanufactured Toyota Yaris Engines

- Remanufactured Toyota Verso Engines

- Remanufactured Vauxhall Engines

- Remanufactured Toyota Landcruiser Engines

- Remanufactured Vauxhall Tigra Engines

- Remanufactured Vauxhall Vectra Engines

- Remanufactured Vauxhall Turbo Units

- Remanufactured Vauxhall Engines

- Remanufactured Vauxhall Meriva Engines

- Remanufactured Vauxhall Mokka Engines

- Remanufactured Vauxhall Movano Engines

- Remanufactured Vauxhall Insignia Engines

- Remanufactured Vauxhall Signum Engines

- Remanufactured Vauxhall Astra Engines

- Remanufactured Vauxhall Astravan Engines

- Remanufactured Vauxhall Combo Engines

- Remanufactured Vauxhall Corsa Engines

- Remanufactured Vauxhall Corsavan Engines

- Remanufactured Vauxhall Zafira Engines

- Remanufactured Vauxhall Adam Engines

- Remanufactured Vauxhall Agila Engines

- Remanufactured Vauxhall Ampera Engines

- Remanufactured Vauxhall Antara Engines

- Remanufactured Volkswagen Engines

- Remanufactured Volkswagen Vento Engines

- Remanufactured Volkswagen Engines

- Remanufactured Volkswagen Sharan Engines

- Remanufactured Volkswagen Polo Engines

- Remanufactured Volkswagen Passat Engines

- Remanufactured Volkswagen Lupo Engines

- Remanufactured Volkswagen LT Engines

- Remanufactured Volkswagen Golf Engines

- Remanufactured Volkswagen Fox Engines

- Remanufactured Volkswagen Eos Engines

- Remanufactured Volkswagen Crafter Engines

- Remanufactured Volkswagen Caravelle Engines

- Remanufactured Volkswagen Caddy Engines

- Remanufactured Volkswagen Jetta Engines

- Remanufactured Volkswagen Amarok Engines

- Remanufactured Volkswagen Touareg Engines

- Remanufactured Volkswagen Touran Engines

- Remanufactured Volkswagen Phaeton Engines

- Remanufactured Volkswagen Transporter Engines

- Remanufactured Volkswagen Tiguan Engines

- Remanufactured Volkswagen Up Engines

- Remanufactured Volvo Engines

- Remanufactured Volvo Engines

- Remanufactured Volvo XC90 Engines

- Remanufactured Volvo XC70 Engines

- Remanufactured Volvo XC60 Engines

- Remanufactured Volvo V70 Engines

- Remanufactured Volvo V60 Engines

- Remanufactured Volvo V50 Engines

- Remanufactured Volvo V40 Engines

- Remanufactured Volvo S80 Engines

- Remanufactured Volvo S60 Engines

- Remanufactured Volvo S40 Engines

- Remanufactured Volvo C70 Engines

- Remanufactured Volvo C30 Engines

Contact Info

0208-133-6004

0208-133-6004 info@mkmotors.com

info@mkmotors.com

Remanufactured Engines

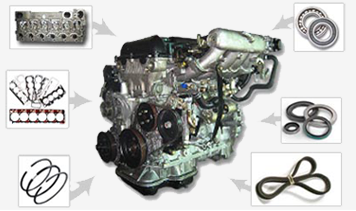

A remanufactured engine is a unit that is rebuilt according to the original equipment specification. Typically a remanufactured engine will have a mixture of brand new and second hard parts combined to rebuild the engine back to its original factory setting.

In addition to offering an excellent solution for consumers, remanufacturing an engine is considered to be a high level form of recycling which not only helps conserve energy and raw materials but also helps in reducing levels of air pollution.

All Remanufactured Engines for Sale:

The concept behind remanufactured engines, is to refurbish the bare engine (head/block) closer to its initial manufacturing standards. Its a very delicate process and involves specialised technicians who proceed to strip down the engine and rebuild it. Each engine model has its own specification and configuration, therefore it is imperative that any components used within the engine remanucfacturing process are of a high quality. Upon the completion of the rebuild/remanufacture/reconditioning of an Engine the unit is then ready to be shipped to clients or fitted directly into the vehicle depending on the client's needs.

Due to this highly specialised procedure, the completed remanufactured engines receive a long warranty to compliment the quality of the unit.

If clients have any questions on the process or require further clarification on the above please do not hesitate to touch base with a MKL Sales Person.

Production Process for Remanufactured Engines :

Dismantling and Inspection:

The Engine is disassembled to its individual components for inspection of wear and tear. The engine is then fully de-greased using a hot steam pressure wash.

Parts Replacement

The Engine will then go through a rigorous reconditioning process where a core number of internal parts are replaced irrespective of condition. If cylinder heads are found to have cracks, they are replaced with a brand new complete cylinder head.

Assembly

The engine is then assembled with the correct torque settings applied to the new head bolts and the camshaft is checked for alignment and then polished before fitment.

MKL Global Ltd trading as MKL Motors